Cooling Tower – a crucial part when it comes to running a chemical process plant as it is necessary for cooling water utility in the plant. There are different cooling tower types, which we discussed in the previous post, along with the working principle.

In this article, we will discuss important cooling tower terms and glossary. Not only terms but we will see calculations i.e. cooling tower efficiency calculation and we also learn about the approach, range, blowdown etc.

You can have a in-depth knowledge by learning what are the Cooling tower dosing chemicals names and purpose.

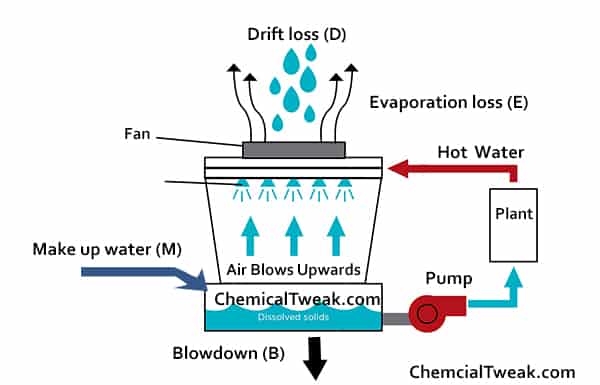

Drift: During operation, some water droplets get entrained and carried out to atmosphere along with air which comes from the bottom. This results in water loss. It is independent water lost by evaporation.

Concentration : The process of increasing solids per unit volume of solution. The concentration of liquid in cooling towers according due to evaporation that cools the water.

Blow Down ; To maintain TDS/concentration of salt water discharged/removed from the system of the cooling tower is known as blowdown water.

Evaporation Loss : During operation, due to air and hot water evaporate from circulating water into the atmosphere.

Drift eliminators : To Minimize the water drifted with air, drift eliminator and hence water loss in cooling water.

Cooling water : Water circulated through cooling the system to cooling system remove heat from areas.

Exhaust Air : The mixture of air and its vapor leaving the cooling tower system.

Louvers : Horizontals in a cooling tower wall to provide the opening through which water enters into system falling water within the tower.

Nozzles: Hot water is sprayed through this device to increase surface area of water and to distribute water evenly in cooling tower

Makeup water:- Water quality which is added to maintain the level which is lost due to drifting and evaporative loss while cooling tower operation is called makeup water.

Cooling tower calculation

1. Cooling tower makeup calculation

Water Make-Up = D + E +B

D = Drift loss

E = Evaporation Loss

B = Blow loss

2. Evaporation Loss = 0.00085 * 1.8 * C * Δt

C = Circulating water in $ {{m}^{{3~}}}/hr$

0.00085 = is the evaporation constant

Δt = Temperature difference between inlet and outlet

Another formula to find the evaporation loss is below

EL = $ \frac{C \cdot C_p \cdot (T_i – T_o)}{\lambda} $

3. Blowdown : B = $ \frac{E}{{\left( {COC-1} \right)}}$

E = Evaporation Loss in $ {{m}^{{3~}}}/hr$

B = Blowdown in $ {{m}^{{3~}}}/hr$

4. COC = Cycle of Concentration

The concentration of Cycle : This is a dimensionless number, and it is the ratio difference between parameters in the solid of cooling water and the solid in makeup water. This value is between 3.0 to 7.0.

COC = $\frac{{Hardness~in~cooling~water}}{{Hardness~in~makeup~water}}$

5. Capacity of cooling Tower

Units in Tons in Refrigeration =

Q =water flow rate

m : Mass flow rate of water in kg/hr

𝐶𝑝: Specific heat of water, typically 1 kcal/kg°C

ΔT: Temperature difference (water inlet temperature − outlet ) in °C.

3024 : Conversion factor (1 TR = 3024 kcal/hr)

As you had read, there are different terms which are associated with the equation to derive equations. Cooling tower performance depends on various parameters which are approach, and range. Let’s go deep and be familiar with these terminologies and derive efficiency.

Prior to know what is approach and range, let us know what is wet bulb temperature and dry bulb temperature.

Wet bulb temperature: Wet-bulb temperature (WBT) is the temperature measured by a thermometer covered in water-soaked cloth/muslin over which air is passed. It is defined as the temperature of a parcel of air cooled to saturation (100% relative humidity) by the evaporation of water into it.

Dry bulb temperature: Dry Bulb Temperature refers to the ambient air temperature. It is called “Dry Bulb” because the air temperature is indicated by a thermometer not affected by the moisture of the air.

Cooling Tower Approach

The approach can be defined as the difference between the Cold Water Temperature (Cooling Tower Outlet) and ambient Wet Bulb Temperature.

Approach = Cold Water Temperature – Wet Bulb Temperature

Cooling Tower Range

Range can be defined as the difference between the Hot Water Temperature (Cooling Tower Inlet) Temperature and Cold water (Cooling Tower Outlet) temperature .

Range = Hot Water Temperature – Cold Water Temperature

Cooling Tower efficiency calculation

Now, let us dive into the calculation of efficiency. It involves the Range and approach of the cooling Tower. Efficiency is limited by the ambient wet bulb temperature. Ideally, cold water temperature will be equal to the wet-bulb temperature which is practically impossible to achieve. Hence, efficiency will be in between 70 to 75%.

Cooling tower efficiency = $\frac{{\left( {Hot~water~temperature-Cold~water~Temperature} \right)*100}}{{\left( {Cooling~tower~inlet~temperature-wet~bulb~temperature} \right)}}$

= $\frac{{Range}}{{Range+Approach}}$

Chemical tweak had a online cooling tower TR calculator, which allows you to calculate cooling tower range, approach, drift loss, efficiency and many more just by entering the data.

FAQ (Cooling Tower efficiency)

1. What Is Cooling Tower Capacity?

Cooling tower capacity refers to the amount of heat a cooling tower can remove from a system, typically measured in tons of refrigeration (TR) or kilowatts (kW). One ton of cooling capacity equals 12,000 BTU/hr (3.517 kW).

2. What is a blowdown in Cooling tower?

Blowdown in a cooling tower is the portion of circulating water that is discharged to remove excess dissolved solids, minerals, and impurities.

3. How Do You Calculate Water Loss In A Cooling Tower?

Water loss in a cooling tower occurs due to evaporation, drift, and blowdown.

Wrapping Up

Hope you like this tutorial on cooling tower equations i.e. efficiency calculation, approach and range. If you have an interest in this topic, then read our tutorial on types of cooling towers, where we covered different types along with diagrams, definitions, and the working principles. If you have any problems regarding this post then feel free to use the comment section.

How to calculate (1) cooling tower flow area (1) the fan capacity

This application can be applicable for pharma industries

Yes these are used in pharma industries.

Absolutely helpful preparing of my promotion interview. Thank you very much.

Dear…

Sir…

I want to know all formula and procedure used by hvac maintance engineer bcs I going to give hvac maintenance engineer interview…

Thanks and regards

How about to calculate the Dirft loss?

Helpful

Thank you boss

great study

Thanks

HOW CAN I CALCULATE WHICH CAPACITY COOLING TOWER REQUIRED ME ON MY PLANT